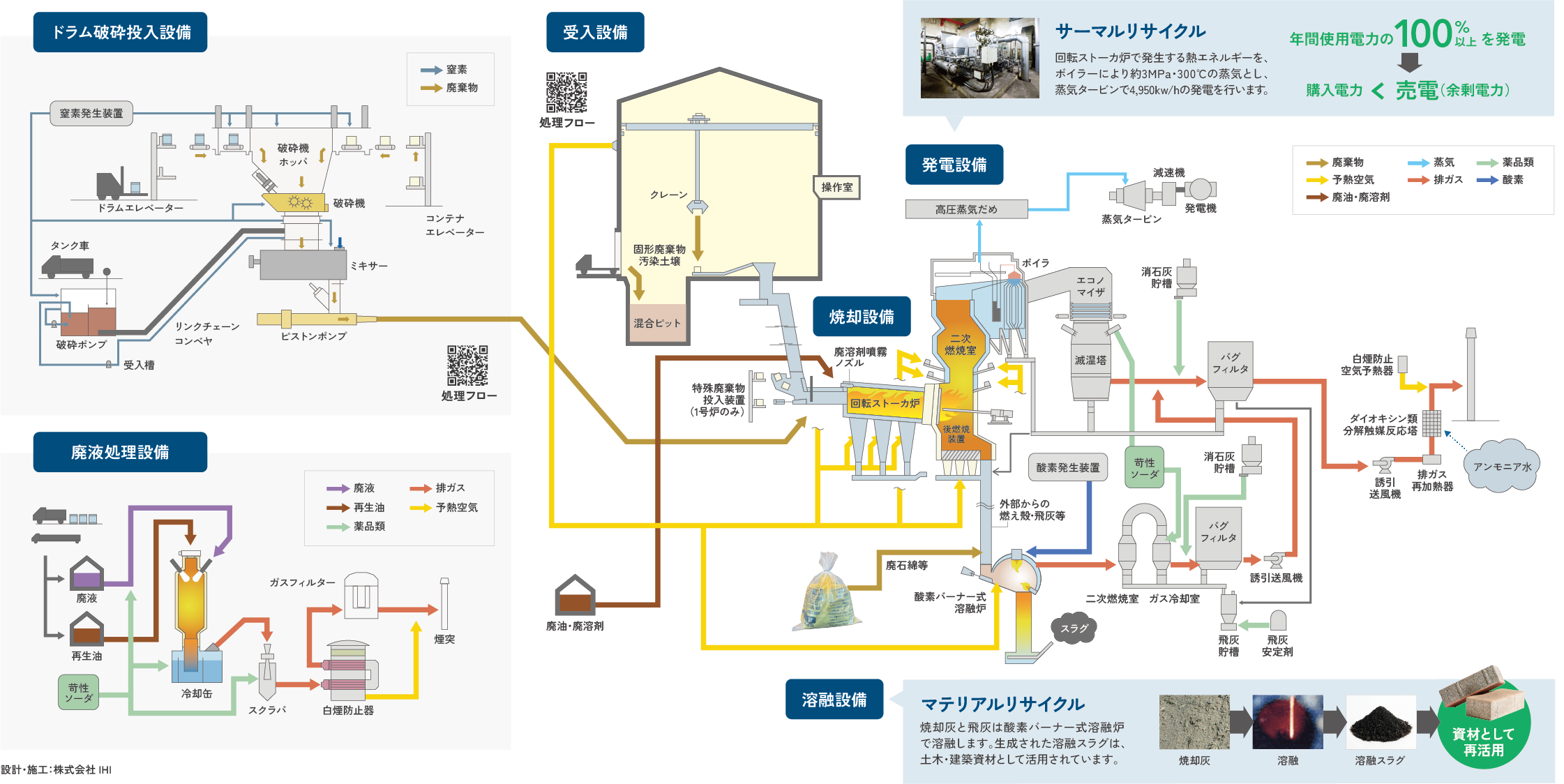

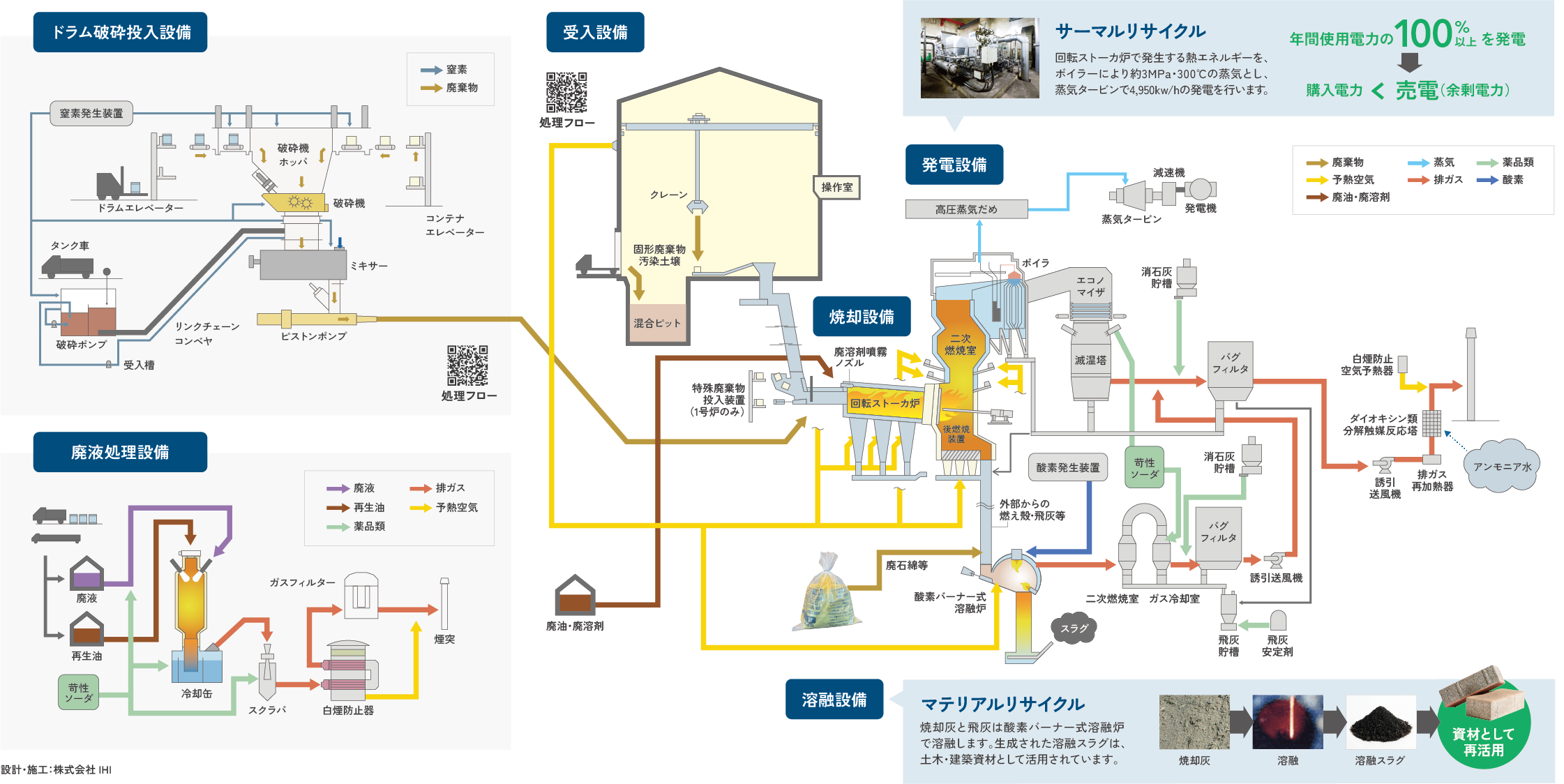

The solid matter incinerator has a daily

processing capacity of 373.8 tons, the

melting furnace has a processing

capacity of 120 tons, and the

submerged combustion furnace has a

processing capacity of 160 tons. In

addition

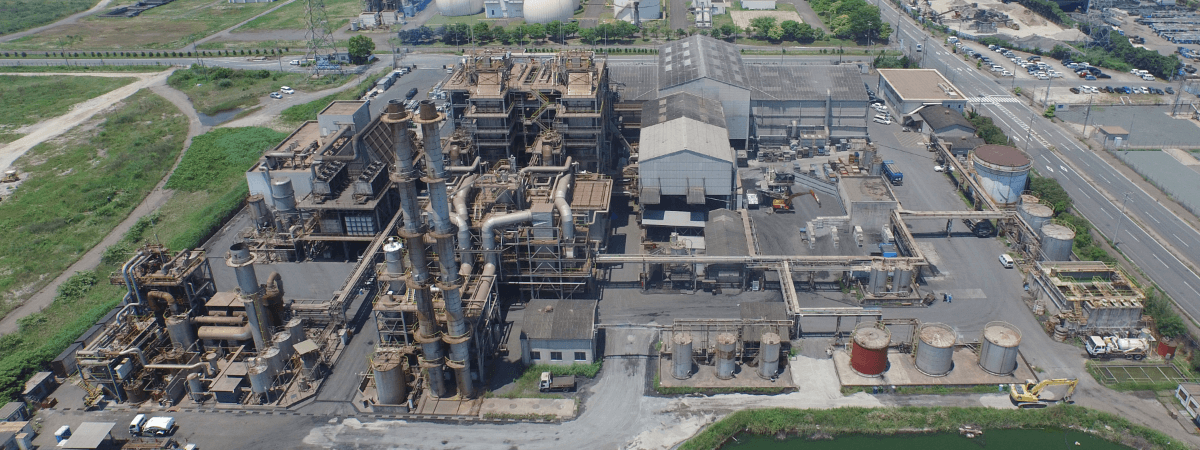

to incineration and storage

facilities, the vast site is fully equipped

with waste liquid treatment equipment

that

does not involve incineration. We

have our own final disposal site on the

adjacent site, and our strength is that we

can consistently undertake everything

from acceptance of waste to

intermediate treatment, recycling, and

landfill. In addition, major feature of the

Fukuyama Plant is that waste can be

carried in by ship.

|

POINT 1 |

Undertaking the processing of industrial waste generated in

wide-scale areas mainly from North Kanto to Kyushu. |

|---|---|

|

Undertaking the processing of industrial waste generated in wide- scale areas mainly from North Kanto to Kyushu. |

|

|

POINT 2 |

Molten slag “Melissa” (civil engineering

and construction materials) is manufactured from incinerated ash. Hiroshima Prefecture registered recycled products |

|

Molten slag “Melissa” (civil engineering and construction materials) is manufactured from incinerated ash. Hiroshima Prefecture registered recycled |

|

|

POINT 3 |

Asbestos detoxification facility certified by Ministry of the Environment.

There are only two certified asbestos detoxification facilities in Japan (as of September 2022) |

|

Asbestos detoxification facility certified by Ministry of the Environment. There are only two certified asbestos |

|

|

POINT 4 |

Thermal energy generated during

incineration is collected as steam, which is used in private power generation as fuel for the plant. 4,950 kW at max |

|

Thermal energy generated during incineration is collected as steam, which is used in private power generation as fuel for the plant. 4,950 kW at max |

|

|

POINT 5 |

At the Environmental Engineering Center,

the advanced analysis of water quality, soil and waste is conducted. |

|

At the Environmental Engineering Center, the advanced analysis of water quality, soil and waste is conducted. |

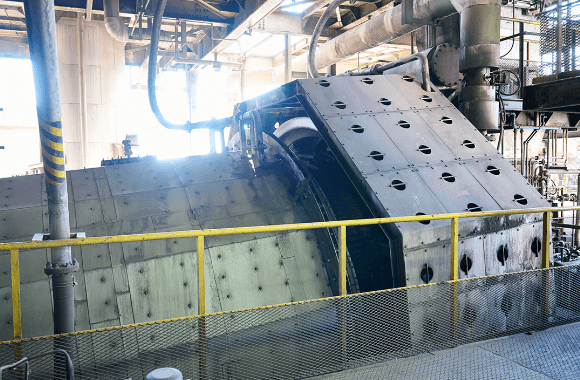

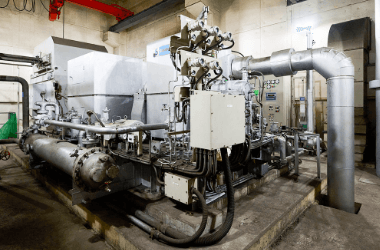

Drum crusher

Revolving stoker furnace

Receiving pit

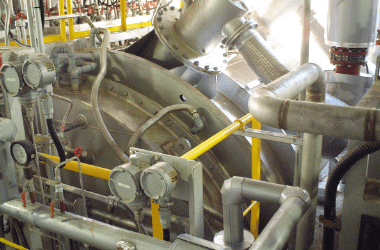

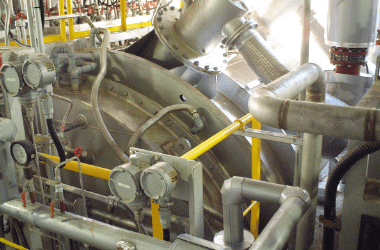

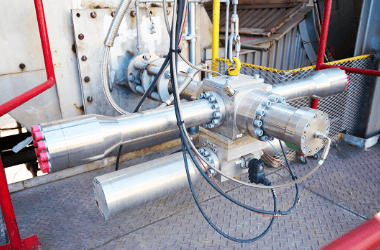

Oxygen burner type melting furnace

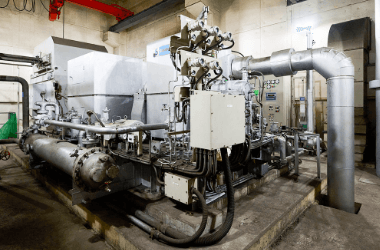

Steam turbine

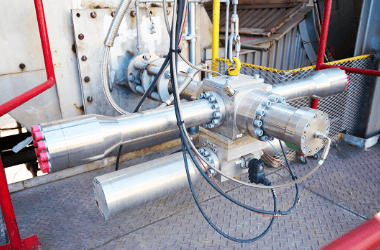

In-liquid incinerator

Shock pulse soot blower

Neutralization equipment

Receiving pit

Oxygen burner type melting furnace

Steam turbine

In-liquid incinerator

Shock pulse soot blower

Neutralization equipment

Processing flow

zoom in

|

Waste to be processed |

|

|---|---|

|

|

|

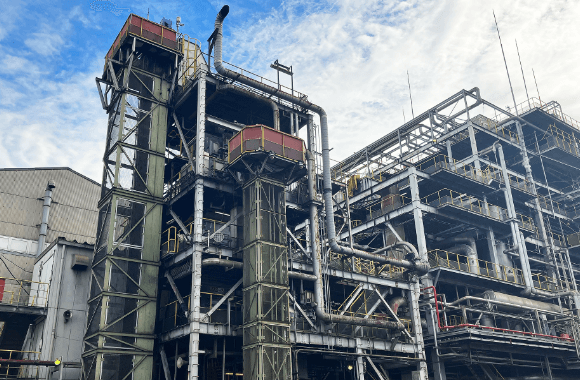

Outline of processing facilities |

|

|

|

|

Outline of preprocessing facilities |

|

|

|

|

Outline of receiving facilities |

|

|

|

|

Outline of final disposal site |

|

|

|

| Pier docking facility |

|

|

|

| Location | |